Precise Sheet Metal Filter Precise Sheet Metal Filter |

Technical advantage:

- The technology of etching changes the traditional way of machining the metal parts by using of lathe and pressing.

- Etching can be used in machining full range of plane parts of metal, alloy, stainless steel, from the micro-filter screen of big area used in conventional industry to the micro-part almost invisible to human eyes.

- It can machine the concavo-convex metal products according to the drawing like character, figure, complicated circularity, design etc.

- Etching can also be applied in making all kinds of perforated parts of close and arbitrary form.

Use covering:

Etching is widely used in all integrated circuit lead frame and other fields, e.g. fluorescent display screen, guard net, precise filter, encoder raster, micro-electrode, mask plate, integrated circuit cover, kinsecope shade mask, SMT, tin-paste net press plate.

Quality guarantee:

Using this technology to machine the parts does not require mould and thus a prompt delivery can be assured. The process from receipt of drawing to delivery only takes about 7 to 10 days.

Technical standard

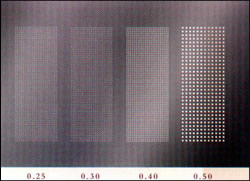

- Minimum wire diameter to be machined:0.02mm

- Max. batch to be machined: 500mm x 600mm

- Thickness of material to be machined: 0.02mm to 0.5mm

- Precision of delineation at machined: 0.01mm

|

|

|

| |

|